Rick Liva RPh, ND

The reality of this industry is that some commonly used botanical extracts and other raw materials used to make natural products have high residual levels of potentially harmful toxic chemicals. Most of us don’t realize that these chemicals may exist in the finished products that we routinely prescribe. Use of these “tainted” materials can be avoided, however. The pursuit of higher profits often is the driver of this problem.

The reality of this industry is that some commonly used botanical extracts and other raw materials used to make natural products have high residual levels of potentially harmful toxic chemicals. Most of us don’t realize that these chemicals may exist in the finished products that we routinely prescribe. Use of these “tainted” materials can be avoided, however. The pursuit of higher profits often is the driver of this problem.

The Problem of Toxic Chemicals in Natural Products

The vast majority of retail and professional manufacturers of natural products do not test for toxic chemical residue in the materials that make up their finished products. We all may be consuming and prescribing these products, which flies in the face of one of the most fundamental and basic philosophical tenants of naturopathic medicine, Primum non nocere.

The company that makes the raw material does not want to spend the money needed to remove the chemical residue and clean it up. It gets sold to the user of the raw material with high levels of residual chemicals.

The manufacturer that purchases the raw material for use in its product does not want to spend the money needed to test and screen the material for residual solvent levels.

I write about this because I wish to educate colleagues and express my outrage about how this happens. It is not a matter of “if” this is happening, but how often it occurs.

In my professional role, I oversee the comprehensive testing for chemical contaminants in raw materials. My goal is to make sure the raw materials that get used have “maximum freedom from contamination.”

Maximum Freedom from Contamination

We live in a time where our food, air and water have some level of contamination. The goal is to do whatever we can to minimize that contamination. We buy organic food, filter our water, use more environmentally friendly personal care and cleaning products; we read labels to avoid as many unacceptable chemicals as possible; and much more. Whether or not we like to admit it, we all have reluctantly accepted that our local and global environment is contaminated to some degree.

The same level of due diligence needs to be applied to natural products. My goal is to find, test and only use materials that have no residual chemical levels, or strive to get the level as low as possible (i.e., maximum freedom from contamination.) This should be the goal of all manufacturers of natural products.

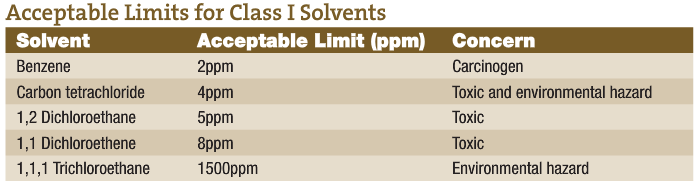

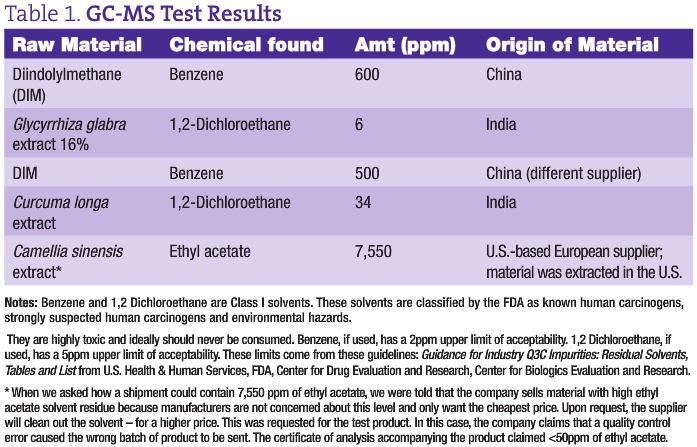

Recently I found several toxic chemicals in raw materials via gas chromatography-mass spectrometry (GC-MS); see Table 1 for the results. The testing performed has routinely found some of these chemicals and others in the past, but this recent spat is alarming. These products came from large suppliers with good reputations for quality.

FDA Protection?

The FDA scrutinizes just a fraction of all imported and domestically produced raw materials used in this industry. In addition, the new FDA Good Manufacturing Practices (GMPs) do not mandate any testing other than identity testing. The FDA leaves it up to the manufacturer to decide if chemical solvent residue or other contamination testing is necessary. The GMP certification bodies do not mandate or require it, either.

Source of Materials

Contamination in natural products is a huge issue, whether the material comes from China, India, Europe or the U.S. I have found contamination problems with raw materials from all over the world. It is not where the material comes from that really matters, but how thoroughly it was tested for purity before it gets put into a product and sold.

A Solution

Chemical residue is easily found and quantified by GC-MS testing of raw material. Ask your natural product suppliers to show you the lot number-specific GC-MS test data to prove their materials have little or no levels of chemical residue. If your supplier does not have this data, consider purchasing product from a company that does this kind of testing.

Chemicals That Might Be Used in Production of Raw Materials

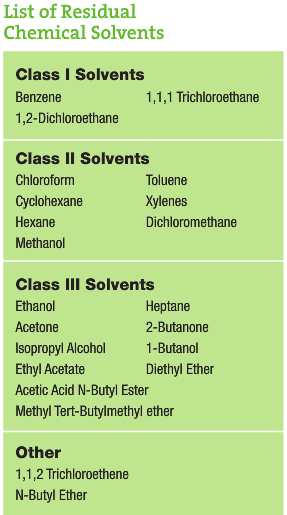

I recommend GC-MS testing for items in the accompanying list and, in most cases, testing every batch of material. Why? I have found suppliers of raw materials not able to provide what chemicals were used in the production of a material. Many times I have been told that chemical X was used, and I also find chemicals Y and Z.

Why test every batch? Distributors that sell raw materials can and often do change their suppliers, so you never know if you are getting the same material that was clean the last time.

Rick Liva, RPh, ND is the managing physician at the Connecticut Center for Health in Middletown, Conn. He is a founding member of the American Association of Naturopathic Physicians (AANP) and past president of the Connecticut Society of Naturopathic Physicians. He has been involved in dietary supplements manufacturing since 1985 and is the president, CEO and director of quality control and quality assurance at Vital Nutrients, certified by NSF International and the Natural Products Association (NPA) in cGMPs for dietary supplements.

Rick Liva, RPh, ND is the managing physician at the Connecticut Center for Health in Middletown, Conn. He is a founding member of the American Association of Naturopathic Physicians (AANP) and past president of the Connecticut Society of Naturopathic Physicians. He has been involved in dietary supplements manufacturing since 1985 and is the president, CEO and director of quality control and quality assurance at Vital Nutrients, certified by NSF International and the Natural Products Association (NPA) in cGMPs for dietary supplements.